On October 16, the National Radio station LR1 in their morning program “Labrīt!” (Good morning!) featured a story on the project “Sestosenso” implemented at the ISSP UL.

In a remarkable leap towards safer and more efficient robotics, the ISSP UL, together with the consortium partners from Europe, is pioneering a new sensor technology designed to create an innovative "skin" for robots. This advancement aims to improve robots’ perception of their environment and facilitate seamless cooperation with human workers, ultimately enhancing workplace safety and productivity.

The international project, “Physical Cognition for Intelligent Control and Safe Human-Robot Interaction (Sestosenso)” involves collaboration among scientists from Slovenia, Italy, France, the United Kingdom, Switzerland, Sweden, Greece, the Netherlands, and Spain, all working towards a common goal: to make robots more aware of their surroundings. This technology promises to reduce the risks industrial robots pose to workers while ushering in a new era of human-robot collaboration.

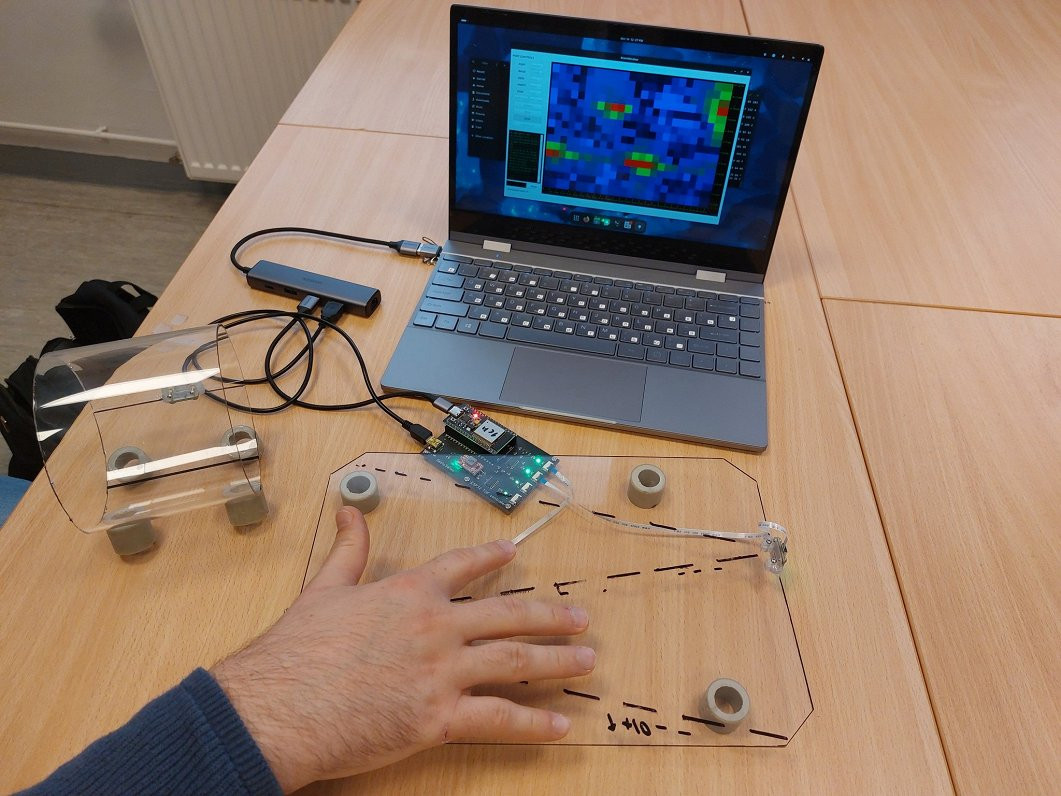

At the recent European Big Data Values Forum, researchers unveiled the Optoskin prototype—a state-of-the-art touch sensor that mimics the functionality of human skin. In the radio story, ISSP UL’s Thin Films Laboratory researcher Andrejs Ogurcovs explains that the innovative design employs light refraction to detect contact points.

When a user presses on a small glass plate equipped with these sensors, the touch triggers a visual response on a computer screen, demonstrating the technology’s sensitivity and precision. "If you press on the glass, the signal turns red, simulating human skin," Ogurcovs explains.

The Optoskin utilizes ordinary acrylic glass combined with commercially available Time-of-Flight (TOF) sensors. These sensors measure distance using laser light, allowing the robot to detect changes in light distribution when touched. This method creates a virtual "light leak," enabling the robot to pinpoint the location of the interaction with remarkable accuracy.

The ISSP UL’s researcher highlights the versatility of the technology. "We’re experimenting with various surface materials, including hard polymers and soft optical silicone, adaptable to any robot shape."

The potential applications of this technology are vast. By integrating Optoskin into robots, factories could see a dramatic reduction in the time and costs associated with reprogramming robots for different tasks. "The goal is to develop a self-aware robot capable of navigating its environment independently," Ogurcovs adds, emphasizing the project’s transformative potential.

As the Optoskin technology continues to evolve, it stands to revolutionize the field of robotics, enhancing safety, efficiency, and collaboration between humans and machines. The future of robotics is not just about automation—it’s about creating intelligent systems that understand and interact with their environment in ways previously thought impossible.

The recording of the story and its transcript in Latvia’s United News Portal (lsm.lv) in Latvian