Early stage researchers Aleksejs Bendins, Liga Jasulaņeca, and Edvīns

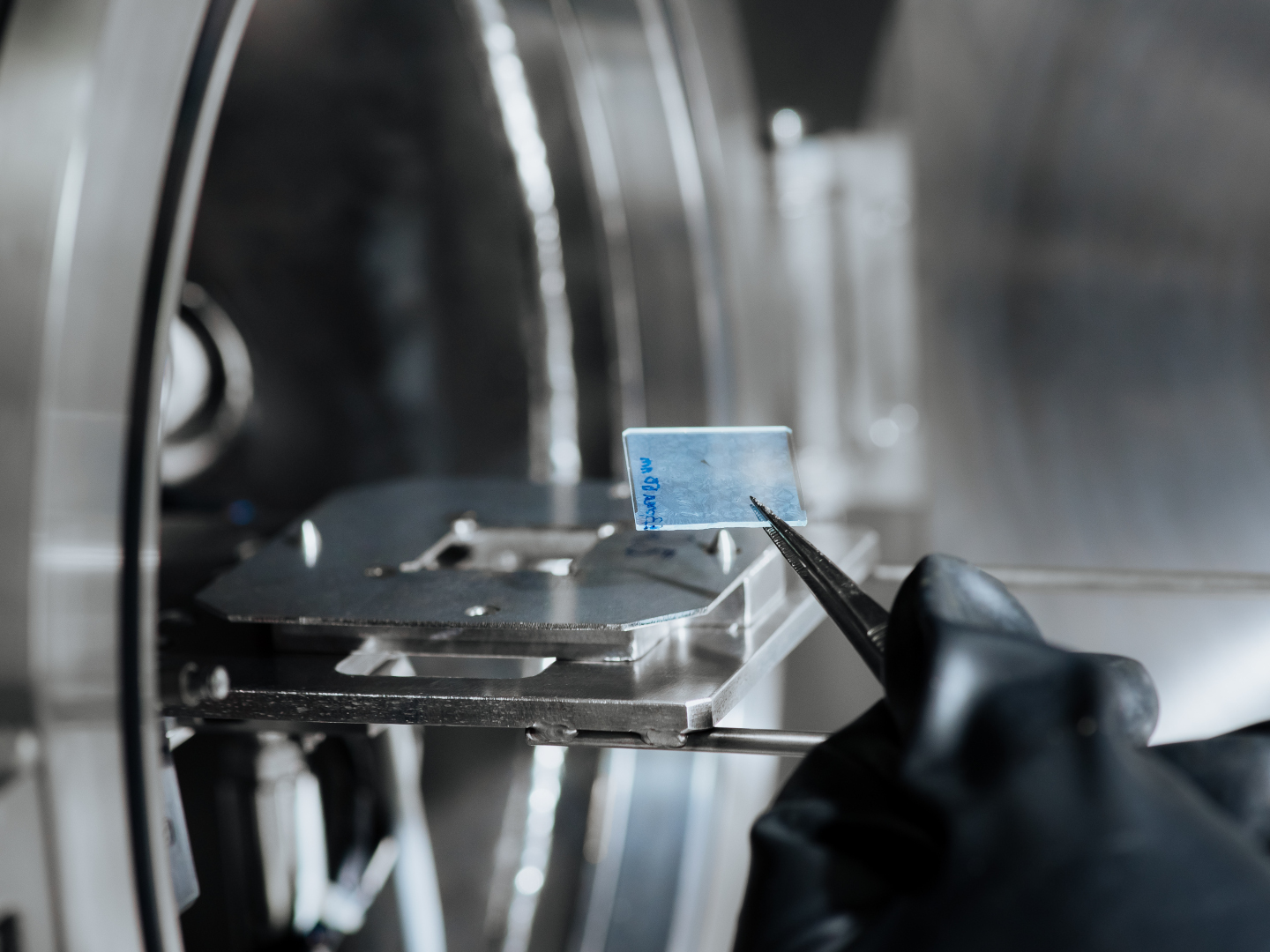

Ļetko from ISSP UL’s Laboratory of Prototyping of Electronic and Photonic Devices visited KTH’s Electrum Laboratory in Kista, Sweden. The purpose of the visit was to become acquainted with the Electrum Lab and its organization, gain experience in atomic layer deposition (ALD) of Al2O3 process, and learn about the oxidation ovens and dry etching.

Tour of the Electrum Lab and cleanrooms introduced the young researchers with the structure, organization, and technical solutions implemented there. The tour improved their knowledge of the constriction and the use of the cleanrooms. ISSP UL’s researchers also gained some experience in solving Al2O3 coating quality issue for organic field-effect transistor (OFET) fabrication with ALD, which was discussed with KTH’s researcher Yong-Bin Wang. The tour participants also could get an insight into oxidation and complementary metal–oxide–semiconductor (CMOS) manufacturing processes presented by the Deputy Director of Electrum Labs and quality engineer Per Wehlin and Associate Professor Per-Erik Hellström respectfully.

The visitors also got acquainted with different dry etching tools available onsite (capacitively coupled plasma (CCP) and inductively coupled plasma reactive ion etching (ICP RIE) types) and had experience exchange with RISE’s development engineer Olof Öberg regarding general dry etching process development techniques. While Electrum KTH has broad range of etching capabilities, it has limited experience in titanium, organics, and glass etching with ICP RIE. There is a lot of potential for ISSP UL’s ICP RIE tool configuration as well as the process development specialists. Since ISSP UL is looking forward to developing titanium and organics etch during upcoming photonic projects, the researchers from Latvia could share their experience with CAMART2 partners from RIX-STO collaboration platform (and beyond) in future.

After the visit, its participants admitted that it was a great opportunity to meet CAMART2 partners at KTH Electrum Lab in person and discuss some process developments and mutual future projects.