On November 27, Latvia’s united news portal lsm.lv published an article, “Latvian scientists study and patent surface coatings for the fight against disease agents”, by the engineer Viktors Vibornijs from the ISSP UL Thin Films Laboratory.

In the article, Viktors describes the fight against microbes from a historical perspective. In the 1860s, Joseph Lister revolutionized British surgery by emphasizing the critical role of sterility in combating disease-causing microorganisms. Today, the pursuit of scientific solutions against pathogenic threats continues, with researchers at the ISSP UL contributing to the fight against bacteria and viruses on surfaces. In an era marked by the Covid-19 pandemic and rising morbidity and mortality from microbial-related diseases, the need for effective solutions in maintaining sterile environments is more pressing than ever.

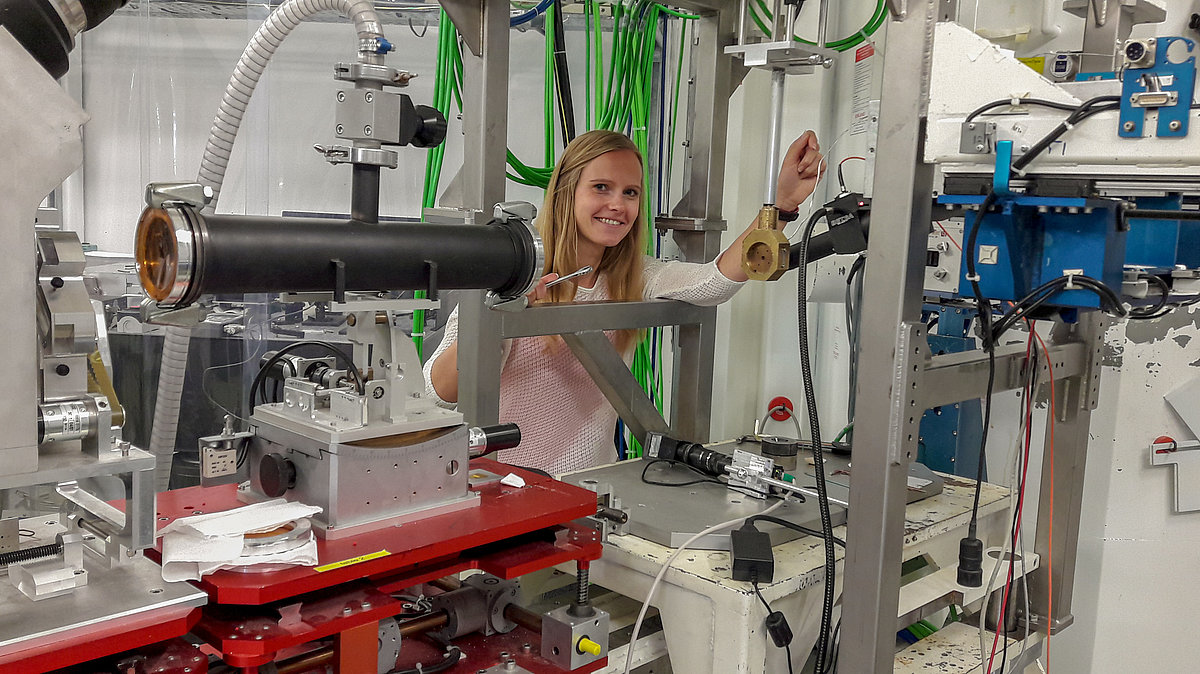

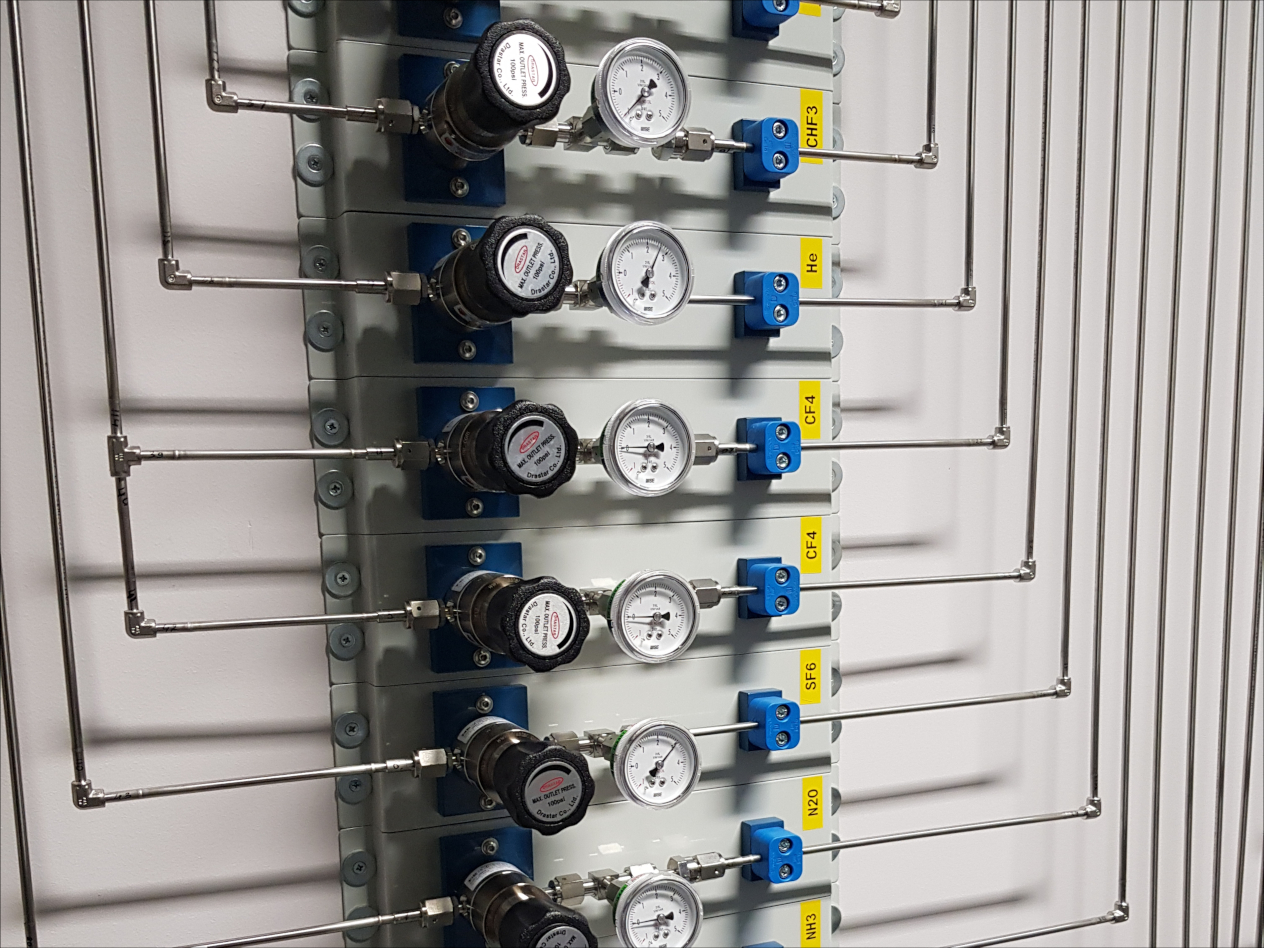

Traditional household sterilization methods often fall short due to the resilience of certain microorganisms. While techniques like UV light irradiation and chemical disinfection are commonly employed, they have drawbacks such as incomplete surface coverage and potential harm to users and the environment. Antimicrobial coatings utilizing materials like copper, silver, titanium, or zinc oxide present an innovative solution. These coatings, applied using magnetron sputtering technology, are effective on various surfaces, including glasses, metals, polymers, and textiles. The ISSP UL’s Thin Films Laboratory has developed a combined copper and tungsten oxide coating, exhibiting superior antimicrobial efficacy, improved optical properties, and mechanical resistance.

After two hours of contact, surfaces treated with this innovative coating have demonstrated the ability to completely inactivate bacteria, such as Escherichia coli and Staphylococcus aureus. This breakthrough has led to the patenting of the technology, and collaborative efforts with Latvian high-tech company SIA Sidrabe Vacuum have paved the way for industrial-scale production. Ongoing research focuses on developing new materials, such as yttrium oxyhydride coating with photochromic properties, anticipating its application in next-generation smart windows. The work at ISSP UL stands as a testament to the continual evolution of antimicrobial technology, offering promising solutions for a safer future.

The antimicrobial coatings were developed within the scope of the ERDF project (No. 1.1.1.1/21/A/050) "Large area deposition technologies of multifunctional antibacterial and antiviral nanocoatings” implemented by ISSP UL and partners from Latvian Biomedical Research and Study Centre and SIA SIDRABE Vacuum.